The Specifications of Topway® Steel PIR Insulated Panel (Roof) TW1000RW

| Standard | Optional | |

| Top Profile: | Trapezoidal | |

| Width(mm): | 1000 | |

| Total Length(mm): | Customized | 2000-13500 (total length = net length + cut back) |

| Cut Back(mm): | No Cut Back | 75 (eaves), 150 (overlap), or 20-300 |

| Core Material Thickness: | Customized | 40mm,50mm, 60mm, 75mm, 80mm, 100mm, 120mm, 150mm, up to 300mm. |

| Top Sheet Thickness(mm): | 0.5 steel | 0.4-0.8 steel, 0.4-0.8 stainless steel and 0.4-1.2 aluminium |

| Bottom Sheet Thickness(mm): | 0.4 steel | 0.4-0.8 steel, 0.4-0.8 stainless steel and 0.4-1.2 aluminium |

| Top Sheet Metallic Coating: | Z40 | Z40-Z275, AZ40-AZ150(For steel only) |

| Bottom Sheet Metallic Coating: | Z40 | Z40-Z275, AZ40-AZ150(For steel only) |

| Top Sheet Finish: | 25um PE(Polyester) | 15-25um PE(Polyester) or 15-25um PVDF or customized |

| Bottom Sheet Finish: | 25um PE(Polyester) | 15-25um PE(Polyester) or 15-25um PVDF or customized |

| Core Material: | PIR(Polyisocyanurate) | |

| Core Material Density(kg/m3): | 42 | 30-45 |

The Cut Back of Topway® Steel PIR Insulated Panel (Roof) TW1000RW

| Standard Eaves Cut Back | 75mm |

| Standard Overlap Cut Back | 150mm |

| Minimum Cut Back | 20mm |

| Maximum Cut Back | 300mm |

Topway® Steel offers cut back service or you can do it onsite. The standard panel is of no cut back.

The total length of the panel = net length + cut back

The tolerances of Topway® Steel PIR Insulated Panel (Roof) TW1000RW

| Panel Length (l)) | Parameter |

| l≤ 3 m | ±5 mm |

| l > 3 m | ±10 mm |

| Panel Width | ±2 mm |

| Panel Thickness(d) | |

| d ≤ 100 mm | ±2 mm |

| d >100 mm | ±2 % |

Dimensional tolerances of Topway® Steel PIR insulated sandwich panels correspond to EN14509 Annex D.

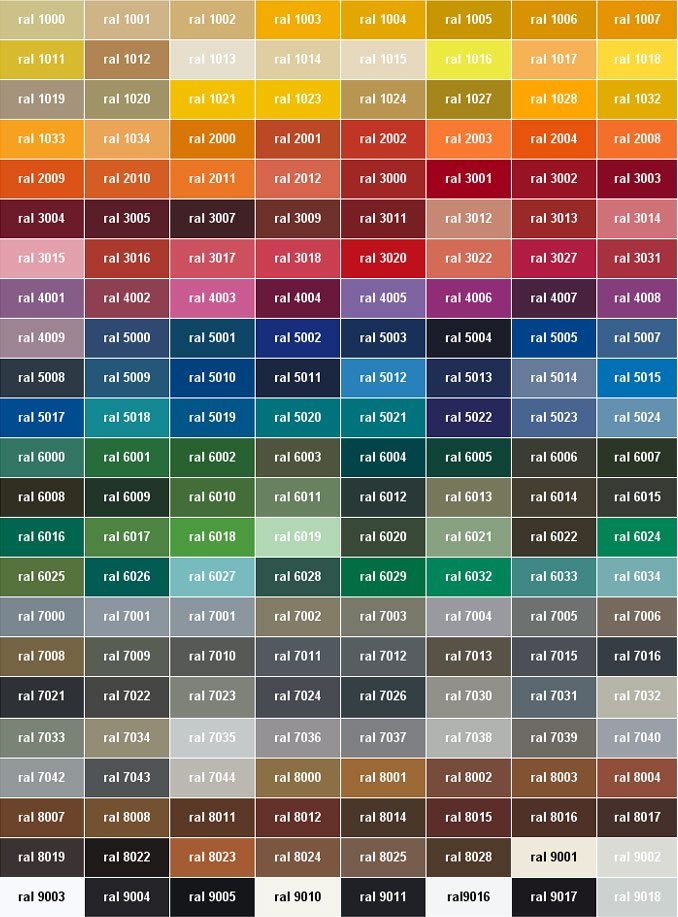

Topway® Steel Colour System

Topway® Steel Colour System is based on RAL Colour System. We can provide any RAL colour you chose. RAL K5 and K7 colour fan deck are both supported. Otherwise, the colour can be made based on your sample.

The technical data of PIR(Polyisocyanurate) core

| Enclose Rate: | 97% |

| Fireproof Rate: | B |

| Water Absorption Percent: | ≤1% |

| Thermal Conductivity: | ≤0.023w/m·k |

| Temperature Range: | -185°C to +120°C |

| Bond Strength: | ≥0.09mpa |

| Compressive Strength: | ≥0.22mpa |

The dimensions, weight & thermal performance of Topway® Steel PIR Insulated Panel TW1000RW

| Core Thickness (mm) | 40 | 50 | 60 | 75 | 80 | 100 | 120 | 150 |

| Overall Thickness (mm) | 75 | 85 | 95 | 110 | 115 | 135 | 155 | 185 |

| U-Value (W/m²K) | 0.47 | 0.35 | 0.31 | 0.25 | 0.23 | 0.18 | 0.15 | 0.12 |

| R-Value (K/m²W) | 2.13 | 2.86 | 3.23 | 4.00 | 4.35 | 5.56 | 6.67 | 8.33 |

| Weight kg/m² 0.5/0.4 Steel | 9.8 | 10.4 | 10.6 | 11.2 | 11.4 | 12.2 | 13 | 14.2 |

| Weight kg/m² 0.7/0.5 Alum | 5.5 | 6 | 6.3 | 6.8 | 7.1 | 7.9 | 8.7 | 9.9 |

The Structural Tables of Topway® Steel PIR Insulated Panel (Roof) TW1000RW

| Single Span | Uniformly distributed imposed load (Kn/m²) Span (m) | ||||||||||

| Core Thickness(mm): | Load Type | 1.4 | 1.6 | 1.8 | 2 | 2.2 | 2.4 | 2.6 | 2.8 | 3 | 3.2 |

| 40 | Pressure | 3.24 | 2.68 | 2.26 | 1.93 | 1.5 | 1.17 | 0.91 | 0.71 | 0.56 | |

| Suction | 4.34 | 3.63 | 3.09 | 2.67 | 2.33 | 1.92 | 1.57 | 1.3 | 1.09 | ||

| 50 | Pressure | 3.86 | 3.27 | 2.8 | 2.43 | 2.04 | 1.63 | 1.31 | 1.06 | 0.86 | 0.69 |

| Suction | 5.23 | 4.46 | 3.87 | 3.39 | 2.99 | 2.58 | 2.15 | 1.8 | 1.53 | 1.31 | |

| 60 | Pressure | 4.21 | 3.6 | 3.11 | 2.71 | 2.34 | 1.89 | 1.54 | 1.26 | 1.03 | 0.85 |

| Suction | 5.72 | 4.92 | 4.29 | 3.78 | 3.35 | 2.85 | 2.41 | 2.07 | 1.78 | 1.53 | |

| 70 | Pressure | 6.86 | 4.19 | 3.67 | 3.23 | 2.87 | 2.38 | 1.97 | 1.64 | 1.37 | 1.15 |

| Suction | 6.65 | 5.8 | 5.12 | 4.55 | 3.88 | 3.23 | 2.73 | 2.34 | 2.04 | 1.79 | |

| 80 | Pressure | 5.19 | 4.52 | 3.98 | 3.52 | 3.13 | 2.67 | 2.22 | 1.86 | 1.56 | 1.32 |

| Suction | 7.15 | 6.27 | 5.56 | 4.96 | 4.12 | 3.43 | 2.9 | 2.49 | 2.16 | 1.9 | |

| 90 | Pressure | 5.69 | 5 | 4.43 | 3.94 | 3.53 | 3.11 | 2.62 | 2.22 | 1.88 | 1.6 |

| Suction | 7.94 | 7.03 | 6.27 | 5.43 | 4.43 | 3.69 | 3.12 | 2.68 | 2.33 | 2.05 | |

| 100 | Pressure | 6.14 | 5.42 | 4.83 | 4.32 | 3.87 | 3.49 | 2.96 | 2.52 | 2.15 | 1.85 |

| Suction | 8.6 | 7.65 | 6.81 | 5.84 | 4.77 | 3.97 | 3.37 | 2.89 | 2.52 | 2.21 | |

| 120 | Pressure | 7.09 | 6.33 | 5.68 | 5.12 | 4.62 | 4.18 | 3.71 | 3.2 | 2.77 | 2.4 |

| Suction | 9.61 | 8.42 | 7.49 | 6.59 | 5.39 | 4.5 | 3.82 | 3.28 | 2.86 | 2.51 | |

| 150 | Pressure | 8.47 | 7.64 | 6.93 | 6.29 | 5.71 | 5.19 | 4.73 | 4.27 | 3.74 | 3.29 |

| Suction | 9.62 | 8.43 | 7.5 | 6.76 | 6.15 | 5.2 | 4.41 | 3.8 | 3.31 | 2.91 | |

| Double Span | Uniformly distributed imposed load (Kn/m²) Span (m) | ||||||||||

| Core Thickness(mm): | Load Type | 1.4 | 1.6 | 1.8 | 2 | 2.2 | 2.4 | 2.6 | 2.8 | 3 | 3.2 |

| 40 | Pressure | 3.24 | 2.68 | 2.24 | 1.85 | 1.56 | 1.34 | 1.16 | 1.02 | 0.9 | 0.8 |

| Suction | 4.07 | 3.27 | 2.71 | 2.29 | 1.98 | 1.74 | 1.54 | 1.38 | 1.25 | 1.14 | |

| 50 | Pressure | 3.81 | 3.02 | 2.46 | 2.05 | 1.74 | 1.5 | 1.3 | 1.15 | 1.02 | 0.91 |

| Suction | 4.24 | 3.43 | 2.86 | 2.43 | 2.11 | 1.86 | 1.66 | 1.49 | 1.35 | 1.24 | |

| 60 | Pressure | 3.97 | 3.15 | 2.58 | 2.15 | 1.83 | 1.58 | 1.38 | 1.22 | 1.08 | 0.97 |

| Suction | 4.32 | 3.5 | 2.92 | 2.5 | 2.17 | 1.91 | 1.71 | 1.54 | 1.4 | 1.28 | |

| 70 | Pressure | 4.23 | 3.38 | 2.77 | 2.33 | 1.99 | 1.72 | 1.5 | 1.33 | 1.18 | 1.06 |

| Suction | 4.45 | 3.63 | 3.04 | 2.61 | 2.27 | 2.01 | 1.8 | 1.63 | 1.48 | 1.36 | |

| 80 | Pressure | 4.38 | 3.51 | 2.88 | 2.42 | 2.07 | 1.79 | 1.57 | 1.39 | 1.24 | 1.11 |

| Suction | 4.5 | 3.68 | 3.09 | 2.65 | 2.32 | 2.05 | 1.84 | 1.66 | 1.52 | 1.39 | |

| 90 | Pressure | 4.6 | 3.7 | 3.05 | 2.57 | 2.2 | 1.91 | 1.68 | 1.49 | 1.33 | 1.19 |

| Suction | 4.47 | 3.67 | 3.09 | 2.66 | 2.32 | 2.06 | 1.85 | 1.68 | 1.53 | 1.41 | |

| 100 | Pressure | 4.78 | 3.85 | 3.18 | 2.69 | 2.3 | 2 | 1.76 | 1.56 | 1.4 | 1.26 |

| Suction | 4.6 | 3.78 | 3.19 | 2.75 | 2.41 | 2.14 | 1.92 | 1.74 | 1.59 | 1.46 | |

| 120 | Pressure | 5.15 | 4.17 | 3.46 | 2.93 | 2.52 | 2.19 | 1.93 | 1.72 | 1.54 | 1.39 |

| Suction | 4.64 | 3.83 | 3.25 | 2.8 | 2.46 | 2.19 | 1.97 | 1.79 | 1.63 | 1.51 | |

| 150 | Pressure | 5.68 | 4.63 | 3.86 | 3.28 | 2.83 | 2.47 | 2.18 | 1.94 | 1.74 | 1.57 |

| Suction | 4.63 | 3.84 | 3.26 | 2.82 | 2.48 | 2.21 | 1.99 | 1.81 | 1.66 | 1.53 | |

Standard Packing – Sea Transportation

Topway® Steel PIR Insulated Panel (Roof) TW1000RW are stacked top side to the top side. The top, bottom, sides, and ends are protected with foam and timber packing, and the entire palette is wrapped with the protection film. The number of panels in each container depends on the panel thickness and length. The table below is shown as a guide.

| Thickness(mm ) | 20GP (m) | 40HQ (m) | 45HQ (m) |

| 40 | 440.8 | 991.2 | 1134 |

| 50 | 371.2 | 849.6 | 972 |

| 60 | 324.8 | 755.2 | 864 |

| 70 | 301.6 | 660.8 | 756 |

| 75 | 278.4 | 623.6 | 702 |

| 80 | 255.2 | 566.4 | 648 |

| 90 | 232 | 519.2 | 594 |

| 100 | 208.8 | 472 | 540 |

| 120 | 185.6 | 424.8 | 486 |

| 150 | 139.2 | 330.4 | 378 |

| 200 | 116 | 236 | 270 |

The length of the panel loaded in 20GP is 5.8m.

The length of the panel loaded in 40HQ is 11.8m.

The length of the panel loaded in 45HQ is 13.5m.

Topway® Steel is dedicated to technologies and methods of building a low carbon world. Topway® Steel PIR Insulated Panel and PUR Insulated Panel System with the industry’s most thermally efficient core, better energy efficiency, fire safety weather resilience, health, and aesthetics, is a gift to our world, and make sure our children’s better future.

PIR Insulated Panel or Polyisocyanurate Insulated Panel are composed of 3 layers, the top layer and bottom layer are corrugated coated Galvanized Steel, stainless steel or Aluminum sheet, and the core is high-density polyisocyanurate foam. Polyisocyanurate also referred to as PIR, polyiso, or ISO is a thermoset plastic typically produced as a foam and used as rigid thermal insulation.

The starting materials of Polyisocyanurate (PIR) are similar to those used in polyurethane (PUR) except that the proportion of methylene diphenyl diisocyanate (MDI) is higher and a polyester-derived polyol is used in the reaction instead of a polyether polyol. The resulting chemical structure is significantly different, with the isocyanate groups on the MDI trimerising to form isocyanurate groups which the polyols link together, giving a complex polymeric structure.

PIR insulated panel or Polyisocyanurate insulated panel is applied as external walls and internal division walls, installed vertically or horizontally on single or multi-span structure. Such as Industrial buildings, Steel frame structure buildings, Storehouses, and logistic centers, Commercial buildings and offices, Fire Rated Buildings, Agricultural objects, Sports halls, Logistics centers.